MKD U-Bracket Instructions

Original Instructions

These instructions are for defining acceptable MKD800, MKD1000, or MKD1200 U-Bracket installations to a mounting surface and for installing an MKD or MKD-WP Series Loudspeaker to an MKD Series U-Bracket.

IMPORTANT SAFETY INSTRUCTIONS – READ THIS FIRST

Safety Instructions

Read and heed all warnings and safety instructions in this manual before using this product. Failure to follow these precautions may result in damage, injury, or death.

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Clean only with a dry cloth.

6) Install loudspeaker in accordance with the manufacturer's instructions.

7) Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus that produce heat.

8) Only use attachments/accessories specified by the manufacturer.

9) Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any way, does not operate normally, or has been dropped.

10) Use personal protective equipment not limited to gloves, safety goggles, ear protection, and lifting supports.

Suspension Warnings

WARNING: Suspending anything, especially overhead of people, should be done with extreme caution. Always engage the services of a certified professional who is qualified to determine the requirements for and to implement overhead rigging. Only persons with the knowledge of proper hardware and safe rigging techniques should attempt to suspend loudspeakers overhead. Failure to follow these precautions may result in damage, injury, or death.

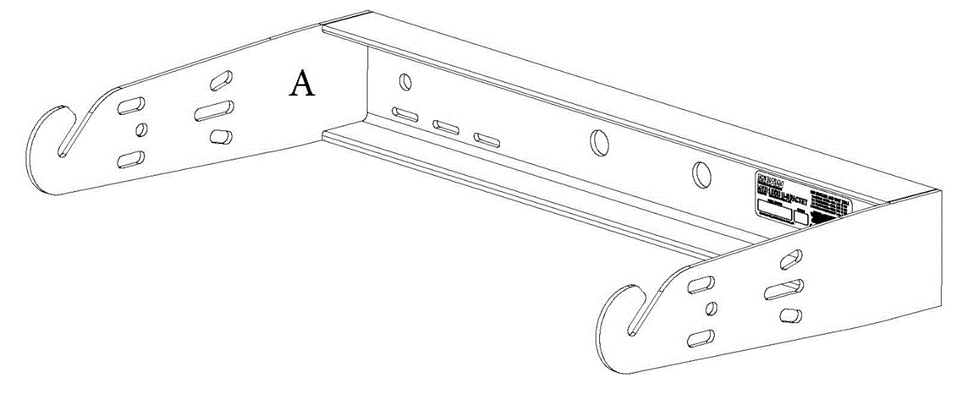

- Inventory

Before beginning installation, inventory your available hardware to items listed.

|

Item |

Description |

Quantity |

|

A |

MKD Series U-Bracket |

1 |

|

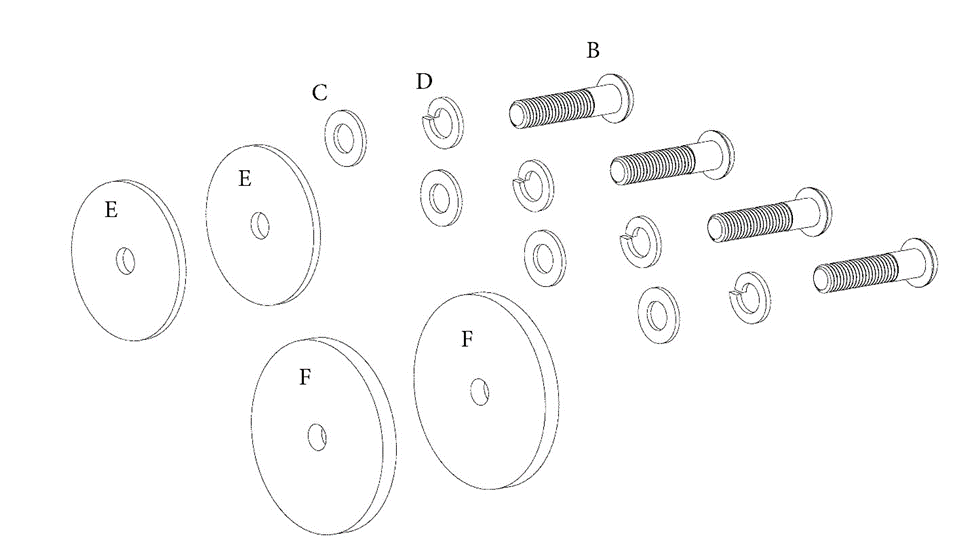

B |

Button Head Screw, M10 X 45mm long |

4 |

|

C |

Flat Washer |

4 |

|

D |

Split-lock Washer |

4 |

|

E |

Rubber Washer, 3mm thick |

2 |

|

F |

Rubber Washer, 6mm thick |

2 |

**Tools Needed: 6mm Allen wrench**

-

- The MKD Series U-Brackets are designed to suspend each corresponding MKD Series loudspeaker with a design factor of 10:1 to meet or exceed most global suspension regulations. Below are the maximum working load limits of each MKD Series U-Bracket at 10:1, 7:1 and 5:1 Design Factors.

|

|

Maximum Working Load Limit |

||

|

Design Factor |

10:1 |

7:1 |

5:1 |

|

MKD800 U-Bracket |

67lb (298N) |

95lb (425N) |

134lb (596N) |

|

MKD1000 U-Bracket |

118lb (524N) |

168lb (748N) |

236lb (1049N) |

|

MKD1200 U-Bracket |

173lb (769N) |

247lb (1098N) |

346lb (1539N) |

These values have been confirmed with Finite Element Analysis and destructive testing

b. The weight/mass of each MKD Series U-Bracket is listed below

|

MKD800 U-Bracket |

5lb (2.3kg) |

|

MKD1000 U-Bracket |

8lb (3.6kg) |

|

MKD1200 U-Bracket |

15lb (6.8kg) |

-

- The MKD Series U-Brackets are designed to suspend only one loudspeaker per u-bracket.

- Any geometric or structural modifications to the MKD Series U-Bracket or hardware are not EAW-approved will void the warranty and may result in damage, injury, or death.

- WARNING: Take care when lifting MKD Series products to avoid harm or damage to product.

- WARNING: MKD U-Brackets are for suspension of loudspeakers only. Suspension of persons is prohibited.

3. Installation of the MKD Series U-Bracket to a mounting surface

-

- Test fit an MKD Series U-Bracket on an MKD Series Loudspeaker to confirm the correct angle, loudspeaker and u-bracket orientation before installing the U-bracket to the mounting surface.

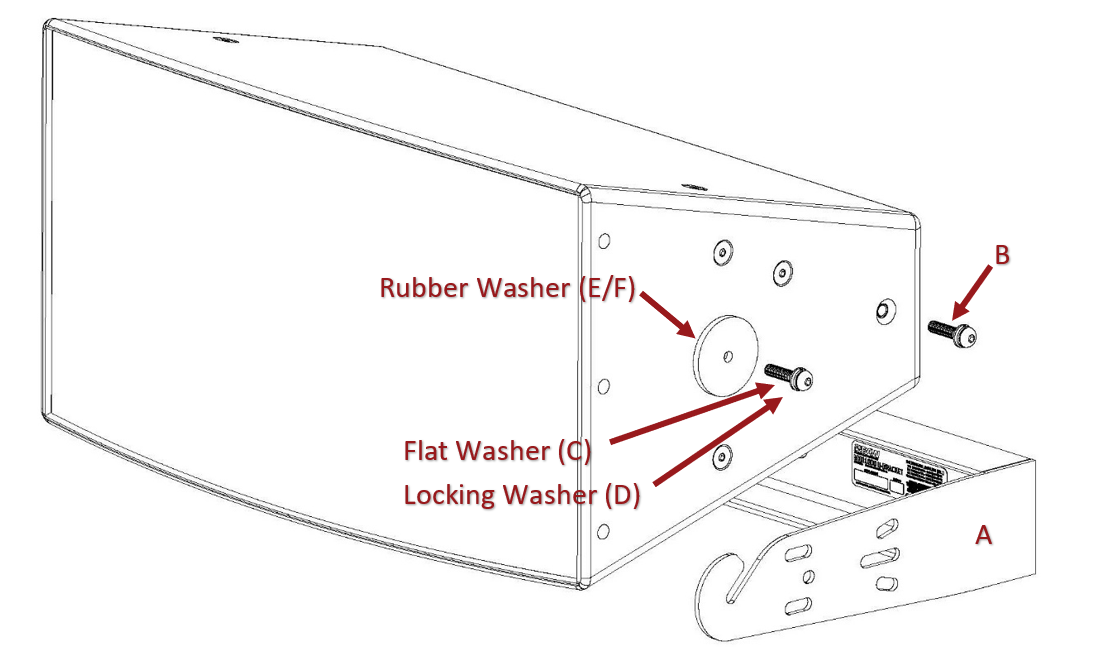

- The MKD Series Loudspeaker may have weather-protected fiberglass shell which increases the size of the loudspeaker. There are multiple sized rubber washers (E and F) included with the MKD Series U-Bracket to accommodate the larger loudspeaker size. Select the rubber washer to best fill the gap between the loudspeaker and u-bracket for use equally on both sides of the loudspeaker.

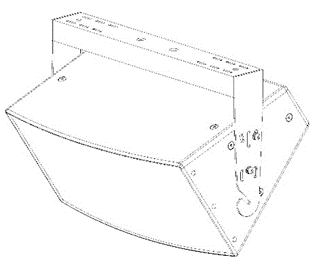

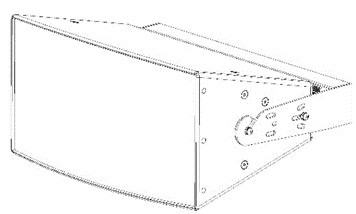

- Configurations - Depending on mounting option used, the MKD Series U-Bracket may be installed horizontal (back and arms are level/parallel to the ground) or downward (back and arms are plumb/perpendicular to the ground). Any other configuration is not an EAW-approved configuration and may result in damage, injury, or death.

|

Downward configuration |

-

- Note, the outermost mounting point “A” is designed as an open slot to allow for easy locating of an MKD Series Loudspeaker and loosely pre-installed hardware. If using the slotted mounting point, the MKD Series U-Bracket must be installed oriented with the slot angled upward, opposing the ground.

|

Horizontal configuration |

-

- Level - The back channel of the MKD Series U-Bracket must be level when installed to the mounting surface and before installing an MKD Series Loudspeaker to the U-Bracket.

- Mounting options

NOTE: It is recommended that you consult a building professional for the proper mounting hardware before mounting the bracket. Due to various construction methods and materials, the hardware for securing the bracket to the mounting surface is not supplied. It is required that the use of hardware locking methods, not limited to lock washers, thread-locker, or nylon-retention feature, be applied when securing the u-bracket to the mounting surface or structure.

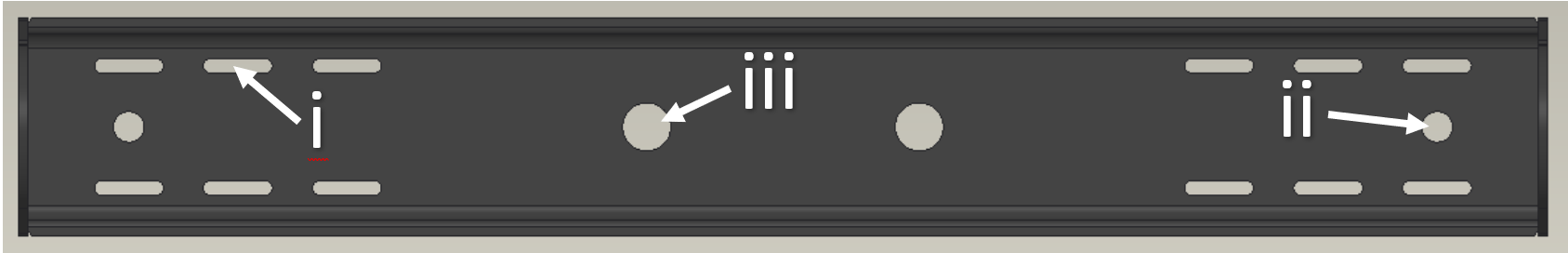

The MKD Series U-Bracket has three mounting options:

-

- Four sets of slots for user supplied M6 or 1/4in hardware.

- These slots are spaced to align for standard stud spacing and allow for slight variations from standard stud spacing.

- If installing the MKD Series U-Bracket by these slots, one slot in each of the four sets must be secured, for a total of 4 slots secured (one slot secured in each of the four quarters of the back channel).

- When installing the MKD Series U-Bracket using the slots, the MKD Series U-Bracket may be installed horizontal (back and arms are level/parallel to the ground) or downward (back and arms are plumb/perpendicular to the ground).

- Two outer Ø9/16in (Ø14.3mm) holes for user supplied M12 or 1/2in hardware.

- These outer holes are spaced to align with holes in common structural channel.

- If installing the MKD Series U-Bracket by the outer holes, both holes must be secured.

- When installing the MKD Series U-Bracket using the outer holes, the MKD Series U-Bracket may only be installed downward (back and arms are plumb/perpendicular to the ground).

- Two inner Ø7/8in (Ø22.5mm) holes for user supplied hardware.

- These inner holes are spaced to align with the input section of an MKD Series Loudspeaker. The two inner holes may be used as a wiring passthrough in a non-structural, non-load-bearing manner with a 1/2in (M16) conduit adapter.

- The two inner holes may be used to structurally install the MKD Series U-Bracket to a mounting surface using load bearing hardware; both holes must be secured.

- When structurally installing the MKD Series U-Bracket using the inner holes, the MKD Series U-Bracket may only be installed downward (back and arms are plumb/perpendicular to the ground).

- Four sets of slots for user supplied M6 or 1/4in hardware.

-

-

- Choosing an MKD Series Loudspeaker configuration

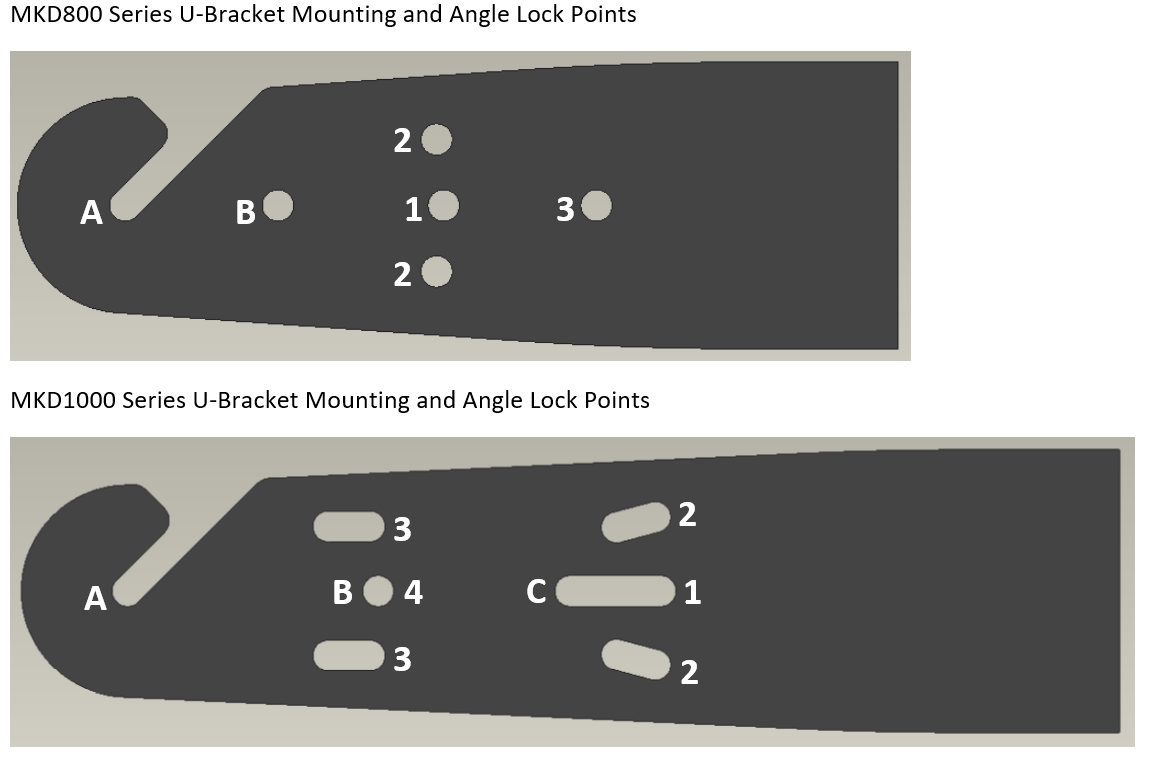

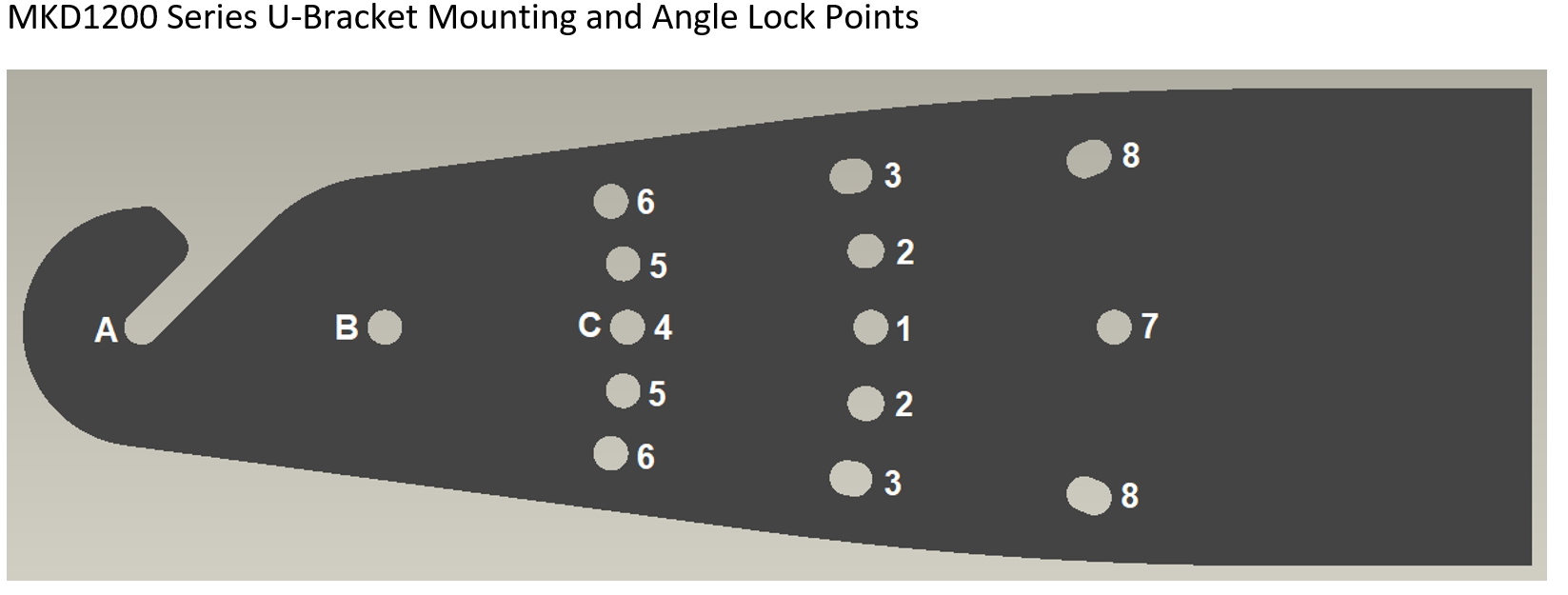

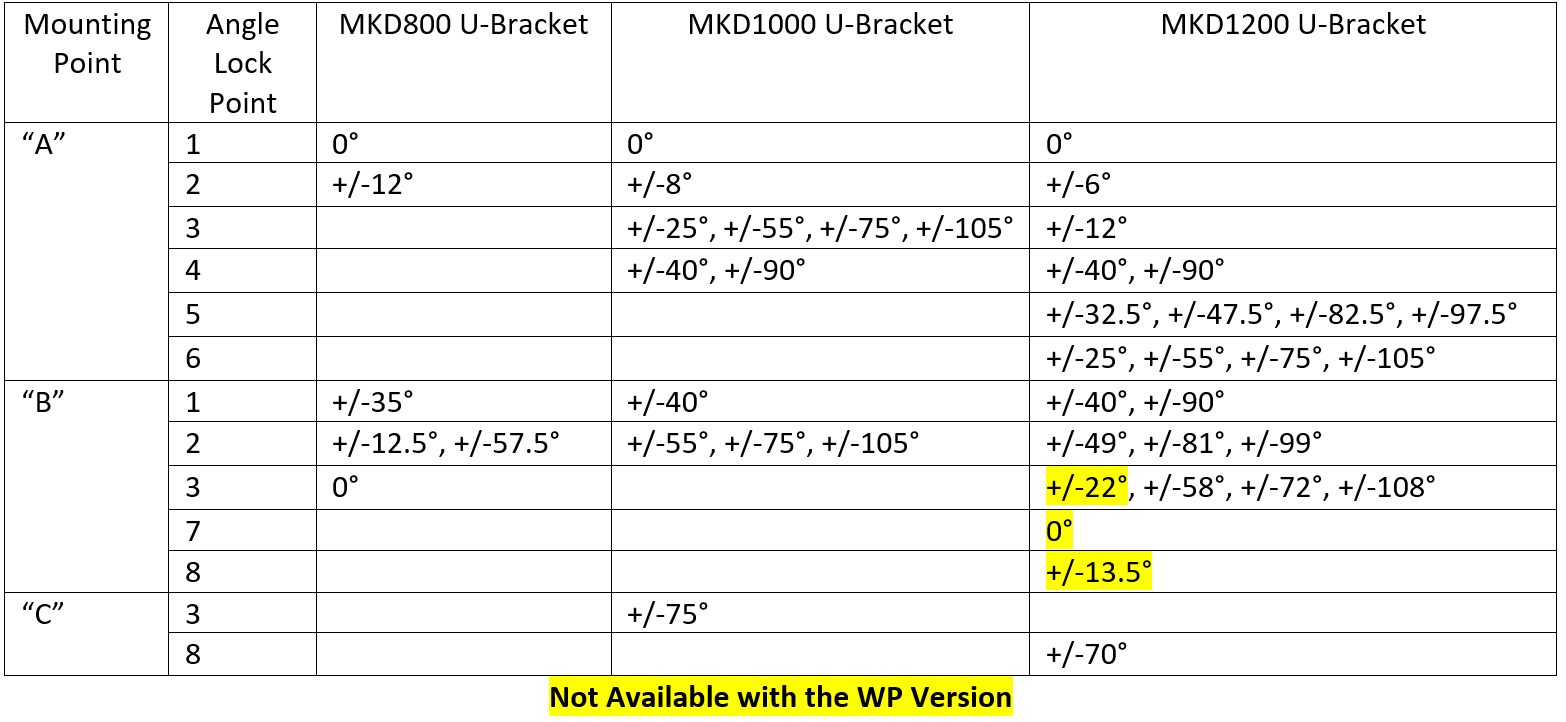

- Each MKD Series U-Bracket has several MKD Series Loudspeaker mounting and angle lock options.

- Mounting points are indicated below by a letter. The varying mounting points offer different distance settings to the MKD Series Loudspeaker from the mounting surface. The varying mounting points also offer different angle lock settings. The selected mounting point is always connected to the MKD Series Loudspeaker using the centermost M10 screw location on the top and bottom of the MKD Series Loudspeaker.

- Note, the outermost mounting point “A” is designed as an open slot to allow for easy locating of an MKD Series Loudspeaker and loosely pre-installed hardware. If using the slotted mounting point, the MKD Series U-Bracket must be installed oriented with the slot angled upward, opposing the ground.

- Angle lock points are indicated below by a number. Use of the angle lock points is optional. The angle lock points are used for locking the MKD Series Loudspeaker at a specific pre-determined angle.

- If an Angle lock point is not used, the loudspeaker may secure the loudspeaker at any angle by torqueing the mounting point hardware.

- Note, there is an additional M10 screw in the bottom of each MKD Series loudspeaker. This one location allows for additional angle lock settings when using the MKD Series U-Bracket.

- The mounting points offer the following lock angles when used in conjunction with the angle lock points. These angles are measured from perpendicular to the mounting surface. For a wall-mount configuration, 0° is aiming directly away from the mounting surface. For a ceiling-mount configuration, 0° is aiming directly downward.

- Choosing an MKD Series Loudspeaker configuration

-

-

- Test fit an MKD Series U-Bracket on an MKD Series Loudspeaker to confirm the correct angle, loudspeaker and u-bracket orientation before installing the U-bracket to the mounting surface.

-

- Removing existing hardware

- MKD Series U-Brackets are mounted to MKD Series Loudspeakers using a button head screw located at the center of the top and bottom of each loudspeaker.

- Using a 6mm Allen wrench, remove the flat head screws located at the center of the top and bottom of the MKD Series Loudspeaker.

- If choosing to use the MKD Series U-Bracket angle lock points, locate the flat head screw in the loudspeaker that corresponds with the intended install angle. Using a 6mm Allen wrench, remove the flat head screw from the threaded point that will be used for locking the angle.

- The MKD Series Loudspeaker may have weather-protected fiberglass shell which increases the size of the loudspeaker. There are multiple sized rubber washers (E and F) included with the MKD Series U-Bracket to accommodate the larger loudspeaker size. Select the rubber washer to best fill the gap between the loudspeaker and u-bracket for use equally on both sides of the loudspeaker.

- Installing the MKD Series Loudspeaker onto a mounted MKD Series U-Bracket.

- WARNING: Take care when handling and wear PPE gloves to protect from crushing and impacts with digits, limbs, and/or product.

- Note, for weather protected applications (using MKD-WP Series Loudspeakers), apply user-supplied, waterproof, non-hardening, non-locking thread sealant to the threads of two button head screws (B) per the thread sealant’s instructions. Failure to do so could result in water ingress and damage to the loudspeaker.

- Onto each of two button head screws (B), place a lock washer (C) and a flat washer (D).

- WARNING HEAVY LIFTING, MULTIPLE PERSON LIFT – Lift the MKD Series Loudspeaker to align the loudspeaker’s center threaded mounting hole with the MKD Series U-Bracket preferred mounting point.

- Using a 6mm Allen wrench, loosely thread the screws and washers (B, C & D) through the MKD Series U-Bracket mounting point, through the selected rubber washer (E or F) and into the loudspeaker’s center threaded mounting hole. Repeat for the opposite side.

- If using the MKD Series U-bracket’s slotted mounting point “A”, the hardware may be preassembled to the MKD Series Loudspeaker.

- Note, if using the slotted mounting point, the MKD Series U-Bracket must be installed oriented with the slot angled upward, opposing the ground.

- Note, for weather protected applications (using MKD-WP Series Loudspeakers), apply user-supplied, waterproof, non-hardening, non-locking thread sealant to the threads of two button head screws (B) per the thread sealant’s instructions. Failure to do so could result in water ingress and damage to the loudspeaker.

- Onto each of two button head screws (B), place a lock washer (C), a flat washer (D) and the selected rubber washer (E or F). Thread these screws and related hardware three complete turns into the loudspeaker’s two center threaded mounting holes.

- Leave as large a space as possible between the rubber washer (E or F) and the flat washer (D).

- WARNING HEAVY LIFTING, MULTIPLE PERSON LIFT – Lift the MKD Series Loudspeaker into the MKD Series U-bracket slots with the large rubber washers (E) inside the u-bracket and the flat and lock washers (C & D) outside the u-bracket.

- Position the MKD Series Loudspeaker to the desired angle.

- If securing the angle using an angle locking point, align the empty threaded hole to the preferred angle locking point.

- Note, for weather protected applications (using MKD-WP Series Loudspeakers), apply user-supplied, waterproof, non-hardening, non-locking thread sealant to the threads of a button head screw (B) per the thread sealant’s instructions. Failure to do so could result in water ingress and damage to the loudspeaker.

- Onto a button head screw (B), place a lock washer (C) and a flat washer (D).

- Using a 6mm Allen wrench, loosely thread the screw and washers (B, C & D) through the MKD Series U-Bracket angle lock point and into the loudspeaker’s center threaded mounting hole. Repeat for the opposite side.

- Using a 6mm Allen wrench, tighten all button head screws (B).

- Removing existing hardware

5. Review the MKD Series Loudspeaker installation

-

- Confirm the loudspeaker is level or plumb depending on the configuration.

- Confirm the aim angle is as expected.

- Confirm all hardware is tight.

- For weather protected applications, confirm all sealants were applied properly.

6. Maintenance of an MKD Series U-Bracket installation

-

- WARNING: Not following Maintenance instructions could result in equipment damage, serious injury or death.

- Maintenance should only be performed by an experienced technician.

- As with any professional loudspeaker system, routine maintenance must be conducted in order to ensure the longevity and safe, consistent performance.

- Inspect the MKD Series U-Bracket for corrosion and other damage. U-brackets with visible damage should be replaced and discarded.

- Inspect hardware securing the u-bracket to the mounting surface for corrosion or looseness. Tighten loose hardware and consider installing hardware locking methods. Replace and discard corroded hardware.

- Inspect hardware mounting the MKD Series loudspeaker to the u-bracket for corrosion or looseness. Tighten loose hardware. Replace and discard corroded hardware.

- For weather protected applications (using MKD-WP Series Loudspeakers), inspect hardware sealants for cracking or gaps in sealant. Replace damaged sealant with user-supplied, waterproof, non-hardening, non-locking sealant per the sealant’s instructions. Failure to do so could result in water ingress and damage to the loudspeaker.

- Clean the MKD Series U-Bracket and MKD Series Loudspeaker with a dry cloth.

7. Dismantling the MKD Series U-Bracket installation

-

- WARNING HEAVY LIFTING, MULTIPLE PERSON LIFT – Fully support the weight of the MKD Series Loudspeaker. Using a 6mm Allen wrench, remove the button head screws at the mounting and angle lock points. Carefully lower the loudspeaker to the ground.

- Support the weight of the MKD Series U-Bracket. Remove the mounting hardware securing the u-bracket to the mounting surface. Carefully lower the u-bracket to the ground.

- Discard all damaged components.

EU Declaration of Conformity

EAW North America Inc hereby declares that this device is in compliance with Directive 2006/42/EC

A copy of this EU Declaration of Conformity is available at https://eaw.com/downloads/#142-660-wpfd-certifications